Polyester fiber for filling : why is length important?

- Sep 6, 2025

- 2 min read

Updated: Sep 30, 2025

The quality of fluffy stuffed products such as sofas, pillows, and blankets is not simply determined by the type of raw material.

In fact, the length of fiber used as filling can greatly affect the resilience, elasticity, feel, and lifespan of the product.

In this post, I will explain in a simple and clear way what role ‘cut length’ plays in polyester fiber for filling and what criteria should be used to select the length.

What is polyester fiber for filling?

Polyester fibers used as fillers usually have the following characteristics:

Staple Fiber Type

3D ~ 15D denier

Including crimp processing (for volume)

Lightweight and excellent resilience with silicon treatment or hollow structure

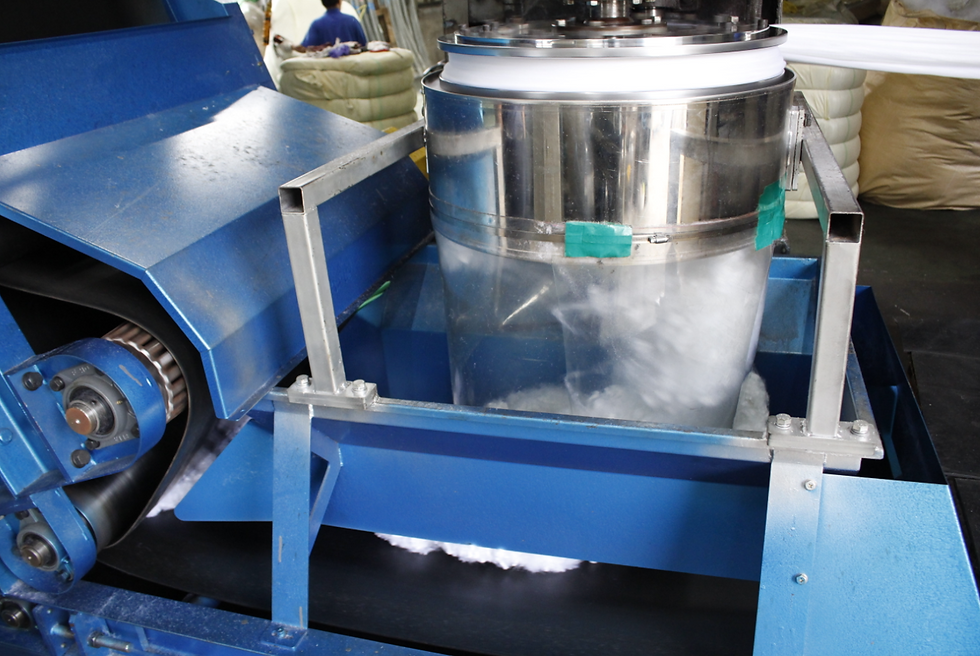

The filler fibers are supplied cut to 32mm, 51mm, 64mm, 76mm, etc. during manufacturing. So what length should you choose to maintain a voluminous shape?

Differences in filler performance depending on fiber length

Fiber Cut Length | Characteristics | Typical Applications |

Below 32mm | Very short, easy to lump, low resilience | Low-cost cushions, disposable products |

51mm | General-purpose, good processability | Budget pillows, standard bedding |

64mm | Standard for high-end filling, excellent elasticity | Hotel bedding, mid-range sofas |

Above 76mm | Very bulky, excellent elasticity, suitable for quilting | Premium bedding, functional padding |

Above 100mm | For special fillings, difficult to process | Custom-made or high-end pillows and bedding |

The longer the fiber, the more obvious the following advantages:

Good return to original shape after compression

Better volume retention

Less clumping and more even distribution

Lower probability of cotton coming out when filling

Why should you avoid fibers that are too short?

Short fibers (e.g. 32 mm) are easy to handle, but can cause problems such as:

After charging, it flattens over time

The product surface is uneven due to clumping

The product lifespan is shortened due to poor resilience after washing

Therefore, for high-end bedding or products that require continuous resilience, it may be advantageous to choose long-staple fibers of 64 mm or more.

Standard length varies

However, the length of fibers for spinning also changes with the development of spinning technology.

In the past, long fibers such as 51 mm were preferred to increase spinning productivity, but this led to increased nipping on the card and decreased workability.

Recently, with the development of high-speed circular knitting machines, the trend toward standardization of 38 mm is becoming stronger, because the fiber length must be appropriately short to reduce spinning defects and enable high-speed spinning.

Therefore, as technology advances, preferences for “standard lengths” may also change.

We at DK FIBER supply polyester fibers for filling with the following specifications:

Denier : 3D / 7D / 15D

Shape : Monofilament, Hollow fiber, Silicone treatment available

Cutting length : 32mm / 51mm / 64mm / 76mm or more

Packing : 250kg PP Bag or customized specifications

We can provide customized supply to partners who value resilience and quality, such as OEM bedding manufacturers, cushion and pad manufacturers, and furniture fabric manufacturers.

Are you looking to improve the quality of your filling products?

Are you looking for a polyester filling fiber with excellent resilience?

DK FIBER can offer you a combination of denier + length to suit your application.