Manufacturing Process of Recycled Polyester Staple Fiber: A Key to Sustainable Textiles

- 민정 박

- 4 ago

- 2 Min. de lectura

As global demand for sustainable materials continues to rise, the manufacturing process of recycled polyester staple fiber (PSF) is becoming a critical topic across the textile and industrial sectors.

This post provides a detailed overview of how recycled polyester staple fiber is produced.

1. What is Recycled Polyester Staple Fiber?

Recycled polyester staple fiber is an eco-friendly synthetic fiber made from post-consumer PET bottles and industrial polyester waste.

It serves as a sustainable alternative to virgin polyester and is widely used in industries such as apparel, home textiles, and automotive interiors.

By reducing plastic waste and conserving petroleum resources, it contributes significantly to the realization of a circular economy.

2. Raw Materials: From PET Bottles to Industrial Waste

The primary raw material for recycled polyester fiber is transparent PET beverage bottles.

Globally, the majority of recycled PSF is derived from these bottles. In addition, industrial by-products such as defective yarns and polyester film waste are also utilized.

However, mechanical recycling is not suitable for mixed-material fabrics or dyed textile waste, which are often incinerated due to processing challenges.

Recently, chemical recycling technologies have been developed that allow for the selective depolymerization and purification of polyester from complex waste streams.This enables the use of dyed garments and blended fibers as viable raw materials.

Such advancements signal a shift in the recycling industry—from a PET bottle-centered system to one capable of handling a broader range of polyester waste.

3. Manufacturing Process: Mechanical Recycling

The primary method used to manufacture recycled polyester staple fiber is mechanical recycling, which reprocesses the fiber without altering its chemical structure.The general steps involved are as follows:

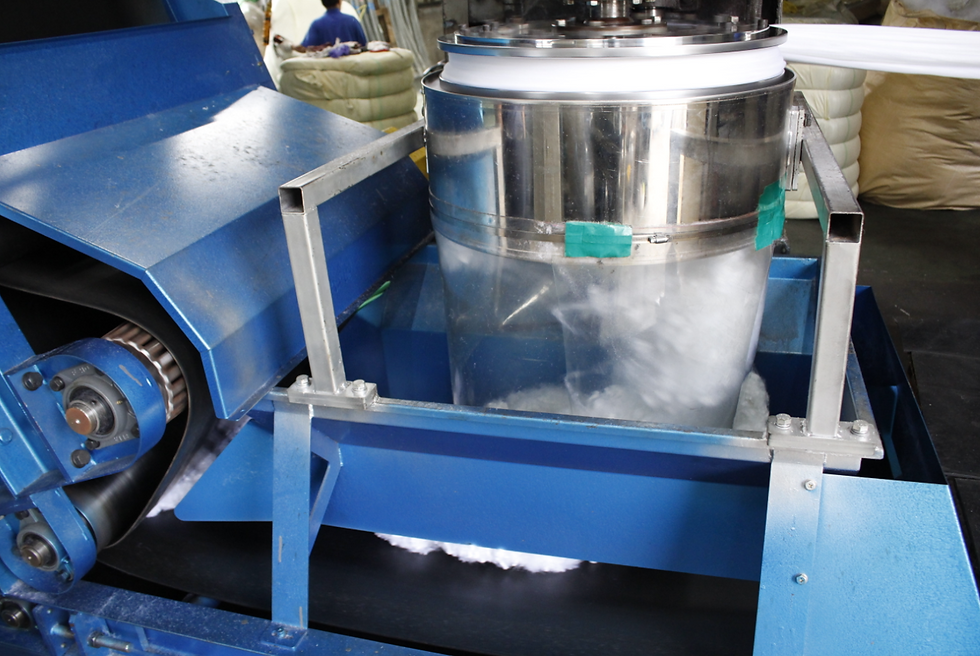

1) Drying and Melting

Removing moisture from the flakes and melting them at 260–280°C

Filtering and extruding to remove impurities

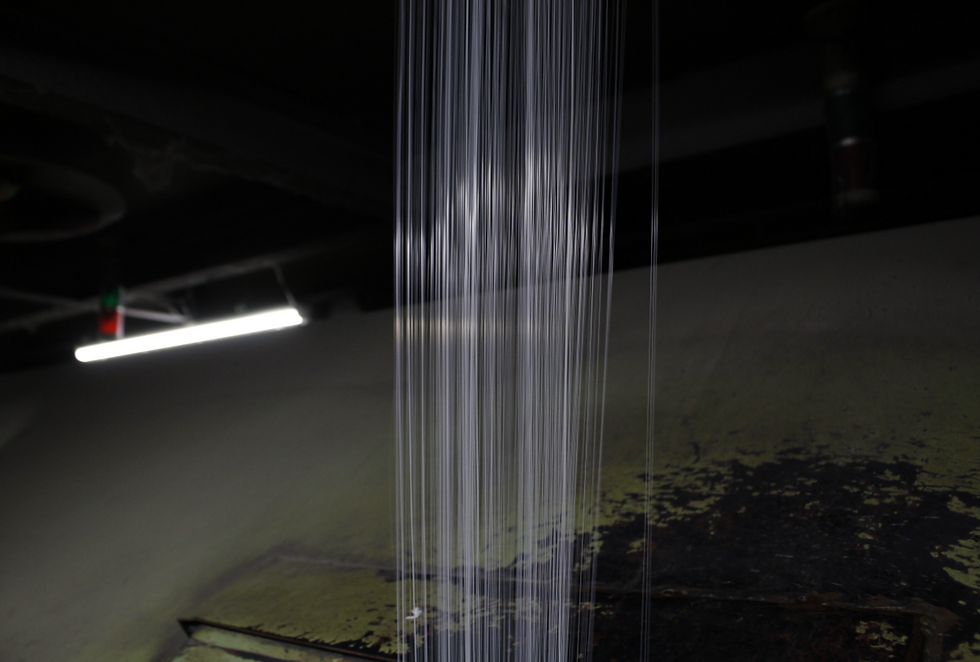

2) Spinning (Melt Spinning)

Extruding molten polyester through spinnerets to form filament fibers

3) Drawing and Cutting

stretching to align polymer chains and improve strength

Cutting into staple fibers of uniform lengths (e.g., 38mm, 51mm)

4) Post-Processing

Additional treatments such as heat setting or washing as needed

Compression packing for shipment

This method is particularly suitable for high-purity, single-material waste like PET bottles.

It offers advantages in simplicity, cost efficiency, and lower energy consumption.

Recycled polyester staple fibers are key industrial materials that are both environmentally friendly and functional.

DK FIBER guarantees a stable supply of high-quality recycled fibers and technological transparency based on GRS certification.